Qualità

Made In Italy

The components used in the manufacture of products Bieffe are 98% recyclable and are all strictly Italian.

Bieffe cooperates for many years with the best Italian suppliers. The boilers and heating elements, the most important components of the machines, are produced in-house under strict control.

The assembly of all the machines is carried out inside Bieffe company, located in Pesaro, Italy. All products are checked after assembly for correct operation. From Italy, finished products are shipped to more than 30 countries worldwide.

Safe and durable products

Copper boilers

The boiler is made of copper, explosion-proof material (cannot explode and, in case of rupture, is not subjet of a components loss).

External resistances

The resistances are external to the boiler, not being in contact with water. They cannot be corroded by limestone.

Teflon Fittings

Electromechanical components are mounted without glue. A teflon wrapping is used for fitting. All machine components can be easily disassembled and replaced.

Copper is a ductile material, that expands with heat. The limestone formations naturally slide down being then removed with a drain tap.

Quality control

During the assembly, all Bieffe machines are scrupulously inspected and tested, even all of his spare parts.

This ensures safety, high quality and durability.

Spare parts

Bieffe always adapts to customer preferences and doesn’t use components of particular manufacture. Anche all spare parts can be easily found on the market.

Proven effectiveness

The effectiveness of our steam against dirt and bacteria

The effectiveness of our steam machines has been proven by scientific analyzes.

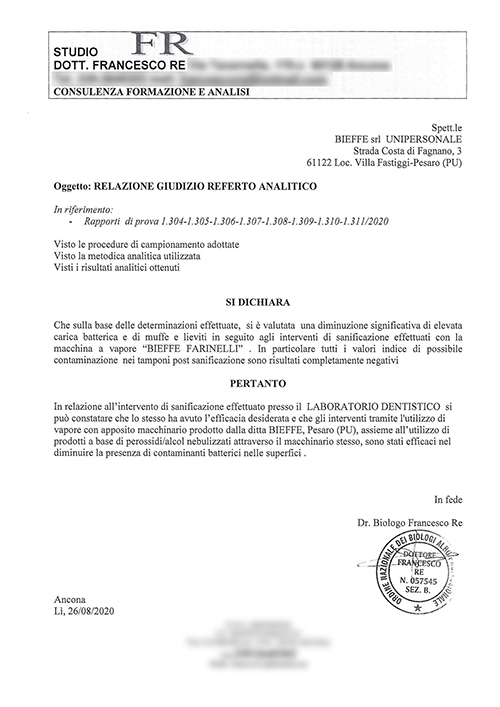

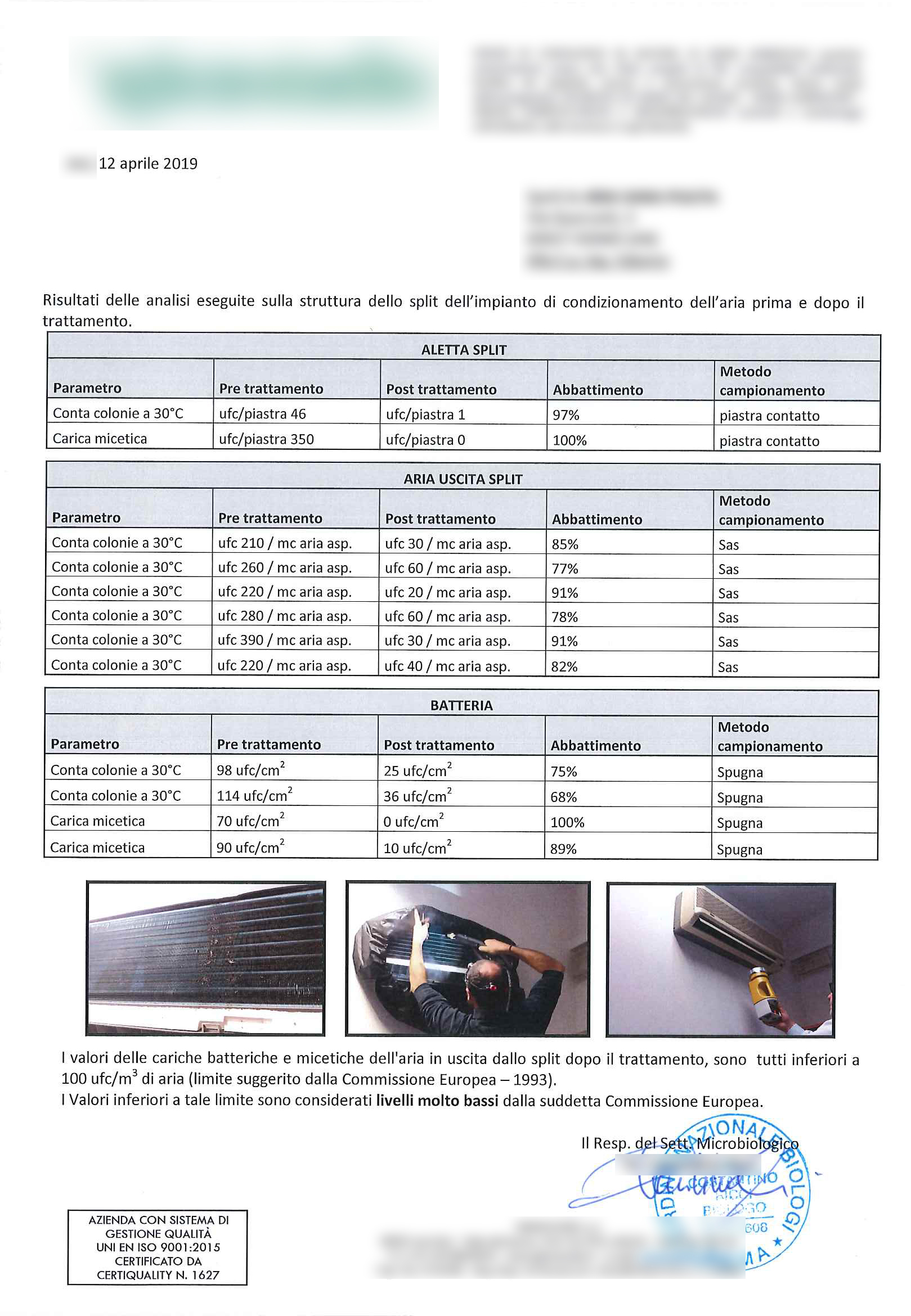

Analyzis carried out on Ariasana

The sanitizing effectiveness of Ariasana, a specific machine for cleaning and sanitizing air conditioners, has been proven by scientific tests that confirm the bacteria killing.

Ecology

The steam, used in early 19th century to develop mechanical energy, is later rediscovered as a source of economic cleaning. Steam continues to induce people to new behavioral and cultural processes combining ecology, economy, safety and health.

Its success is effective cleaning and sanitizing combined with a reduction of energy consumption and of the use of detergents.

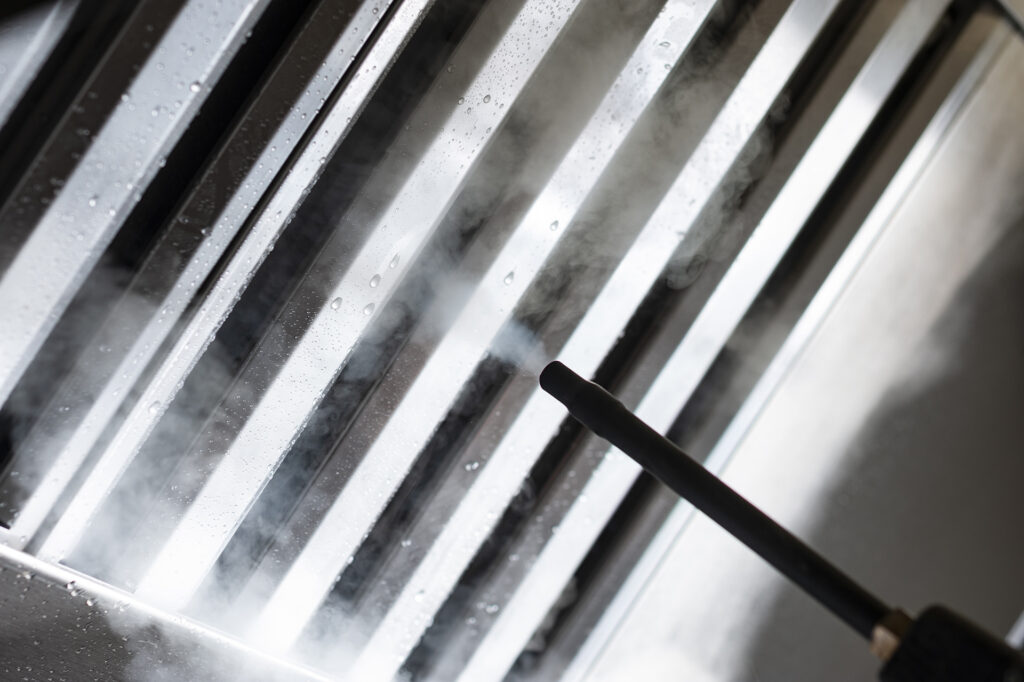

The technology of dry steam

Our technology is based on generating of the dry steam, heated to the temperature between 120 and 170 C°. At this temperature, the steam is able to release an incredible power that eliminates the deep dirt and micro organism without harming environment and damaging fabrics.

Dry steam acts thanks to three key factors:

- The temperature, that is in absolute the main one.

- The micro residual moisture, which acts as a solvent and retains the powder residue.

- The pressure, which increases the cleaning effectiveness in dept.

The pressure and high temperature annihilate microbes, bacteria and the most common allergens, averting the risk of allergies and other diseases related to the use of chemical detergents.

A healthy and sustainable future for the new generations

Steam cleaning does not require additional chemicals to the benefit of those who are sensitive to chemicals or want to reduce the level of toxicity in their homes, especially in the presence of children.

The steam cleaning reduces the water consumption compared to other cleaning methods (it is estimated the production of 1000 liters of steam per liter of water) and does not imply the use of any chemical detergent.